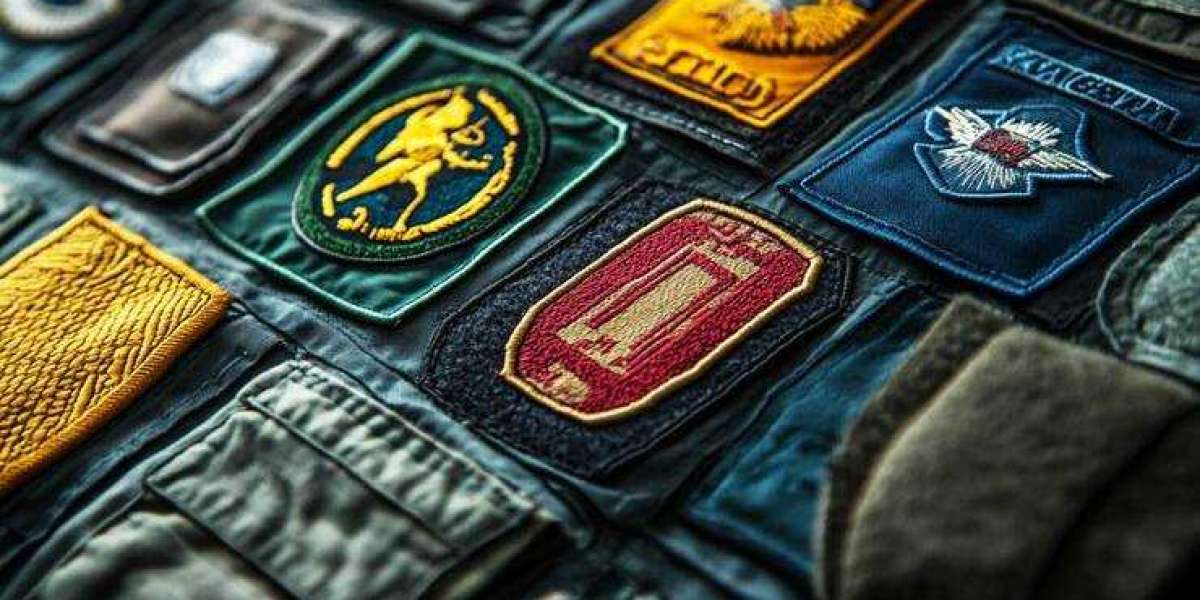

In the world of safety gear and uniforms, durability, visibility, and brand identity are paramount. Whether it's for military personnel, first responders, construction workers, or other professionals who rely on their gear for protection, every element of their uniform must be functional and reliable. One such element that has gained popularity in recent years is custom PVC patches. These patches offer a blend of durability, customization, and aesthetic appeal that makes them an ideal choice for enhancing safety gear and uniforms. This blog will explore the benefits of custom PVC patches, how they can enhance safety gear, and the role of patch manufacturers in creating these essential components.

The Versatility of Custom PVC Patches

Custom PVC patches are made from polyvinyl chloride, a type of plastic known for its flexibility, water resistance, and durability. These qualities make PVC patches ideal for use in environments where uniforms and safety gear are exposed to harsh conditions, including extreme temperatures, moisture, and rough handling. Unlike traditional embroidered patches, which can fray or fade over time, PVC patches maintain their appearance and integrity even after prolonged use.

One of the key advantages of custom PVC patches is their versatility in design. Patch manufacturers can create intricate designs with fine details, vibrant colors, and 3D effects that would be difficult to achieve with other materials. This allows organizations to incorporate logos, text, and other branding elements into their patches, ensuring that their uniforms not only serve a functional purpose but also promote brand identity.

Enhancing Visibility and Safety

Visibility is a critical factor in the design of safety gear, particularly for professionals who work in low-light or hazardous environments. Custom PVC patches can be designed with reflective elements, bright colors, and glow-in-the-dark features to enhance visibility. For example, reflective PVC patches on a construction worker's vest can make them more visible to drivers and machinery operators, reducing the risk of accidents.

Glow-in-the-dark PVC patches are another innovative option that can improve safety in low-light conditions. These patches absorb light during the day and emit a soft glow at night, making the wearer easily identifiable in dark environments. This is particularly useful for emergency responders, military personnel, and outdoor workers who often operate in conditions where visibility is compromised.

Durability and Longevity

When it comes to safety gear and uniforms, durability is non-negotiable. Custom PVC patches are built to last, with a lifespan that far exceeds that of traditional embroidered patches. The material is resistant to water, chemicals, and UV rays, making it ideal for use in challenging environments. Additionally, PVC patches do not fade or lose their shape over time, ensuring that the patch remains as effective and visually appealing as the day it was attached.

The durability of PVC patches also translates to cost-effectiveness. Since these patches do not need to be replaced as frequently as other types of patches, organizations can save money on uniform maintenance and replacements. This is particularly important for large organizations that outfit a significant number of employees with safety gear.

Customization for Specific Needs

Custom PVC patches offer unparalleled customization options, allowing organizations to create patches that meet their specific needs. Patch manufacturers can produce patches in a wide range of shapes, sizes, and colors, with the option to add velcro backing, adhesive, or even sew-on options depending on the application.

For example, a fire department may require patches that withstand high temperatures and exposure to water. Custom PVC patches can be designed to meet these requirements while also featuring the department's logo and other identifying information. Similarly, a security company may need patches that can be easily removed or replaced on uniforms; in this case, velcro-backed PVC patches provide a practical solution.

The ability to customize patches extends beyond just appearance. Patch manufacturers can also create patches with specific textures, such as raised or recessed designs, to add a tactile element to the patch. This can be particularly useful for organizations that want to create a unique, memorable brand experience.

Branding and Identity

For many organizations, safety gear and uniforms are more than just functional attire—they are a key part of their brand identity. Custom PVC patches allow organizations to showcase their logos, slogans, and other branding elements on their uniforms in a way that is both durable and visually appealing. This not only helps to create a cohesive and professional appearance but also reinforces brand recognition among employees, clients, and the public.

In industries where safety gear is worn in public or high-visibility settings, branded PVC patches can serve as a powerful marketing tool. For example, a construction company with workers on a busy job site can use custom PVC patches to prominently display its logo on uniforms and safety vests. This not only enhances the company's visibility but also communicates its commitment to safety and professionalism.

The Role of Patch Manufacturers

The quality and effectiveness of custom PVC patches largely depend on the expertise of the patch manufacturers. Experienced manufacturers have the knowledge and resources to create patches that meet the specific needs of their clients, from choosing the right materials to ensuring precise color matching and design execution.

Working with a reputable patch manufacturer is essential for organizations that require high-quality PVC patches for their safety gear and uniforms. A skilled manufacturer can guide the organization through the design process, helping them to select the best options for their patches and ensuring that the final product meets their expectations.

In addition to quality, turnaround time is an important consideration when selecting a patch manufacturer. Organizations often need patches within tight deadlines, especially when outfitting new employees or launching a new safety initiative. Reliable patch manufacturers understand the importance of meeting these deadlines and have the processes in place to deliver patches on time, without compromising on quality.

Conclusion

Custom PVC patches have become an integral part of safety gear and uniforms across a wide range of industries. Their durability, versatility, and customization options make them an ideal choice for organizations that prioritize safety, visibility, and brand identity. By working with experienced patch manufacturers, organizations can ensure that their PVC patches meet the highest standards of quality and performance, ultimately enhancing the effectiveness of their safety gear and uniforms. Whether it's for military personnel, first responders, or industrial workers, custom PVC patches offer a practical and aesthetically pleasing solution for enhancing safety and professionalism.